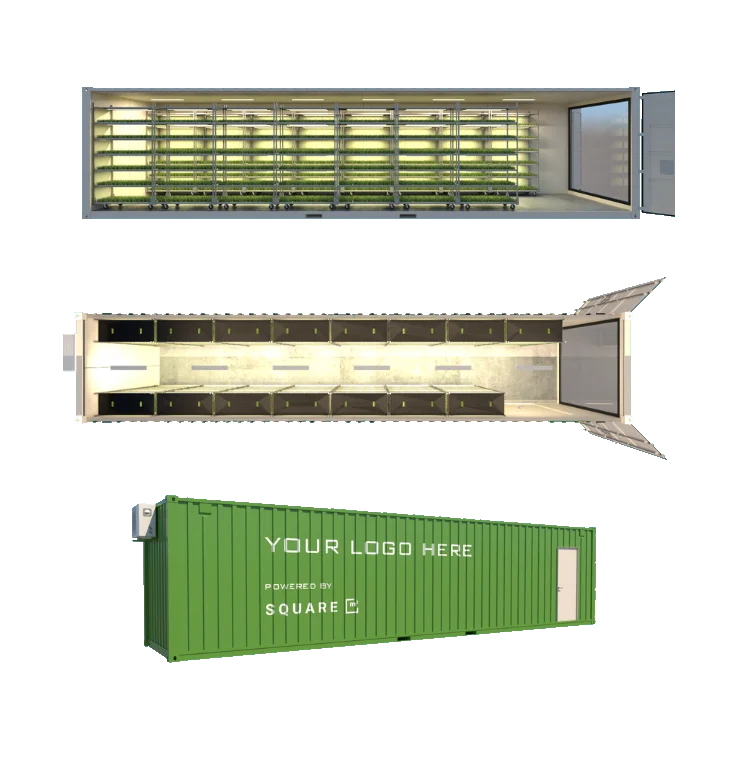

Shipping Container Custom Farm Solution

Apply for consultation

We will contact you within 24 hours.

Hyper-local mobile vertical farming solution

- Container structure assures easy transportation and mobility

- Easy to set up anywhere within minutes

- Insulated container unit assures uninterrupted operation in any conditions (-20°C to +30°C)

- Internal electricity, lighting, water supply, climate and humidity control systems

Up-Cycle

Eco-friendly and recyclable materials in our production

Access

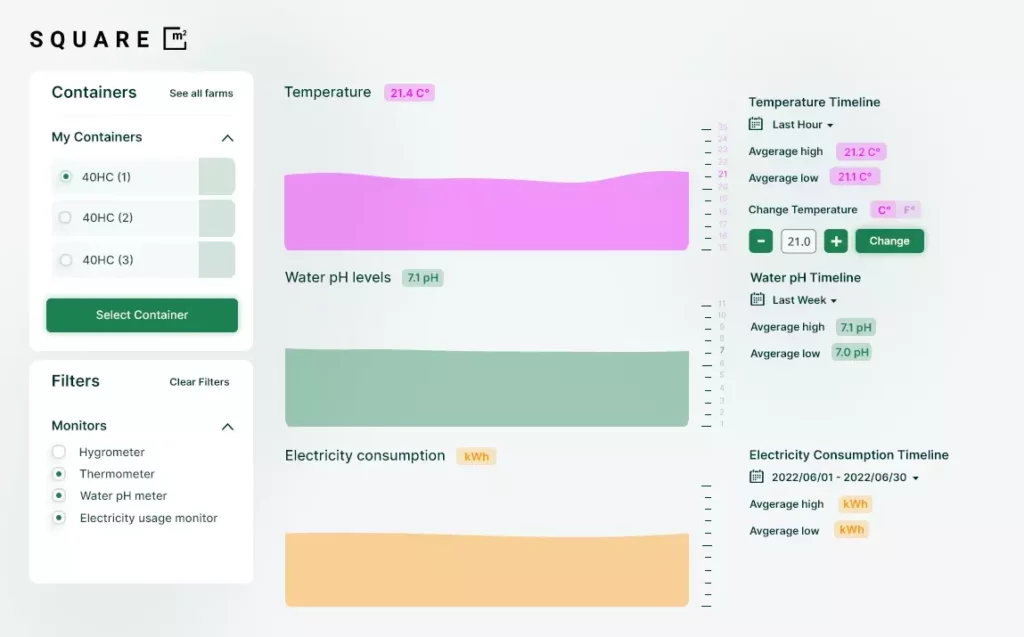

Follow your crop's progress 24/7 online

Ready-To-Grow

We provide fully equipped mobile vertical farming container units plug-and-play

Solar Energy Friendly

We can set up a farm with solar panels or other alternative energy sourcer

Custom

We customize vertical farming solution for your desired local produce

Software

To support easy overview of controls and operations

Vertical Farming vs Traditional Farming

80% LESS ENERGY

85% LESS WATER

90% LESS LAND

95% LESS LOGISTICS

Container Farm

Specifications

- 40-foot shipping container

- 50-60m2 growing area

- Ebb & flow hydroponic system

- Humidity measure automation

- Lighting control automation

- HEPA filters

- Air conditioning and ventilation

- Total electricity needed 10 kW

- Automation and measurement software

Hydroponic growing system

Farmers developed it for farmers with a focus on productivity. It is parametrized to the horticultural standards. It is easy to keep clean, highly customizable to the growing process, and designed in a way that replacement parts can be easily found in most of the hardware shops which eases the maintenance of the system. It is a modular designed system suitable for almost all surfaces and spaces.

The cultivation system is based on the principles of organic cultivation, the user can grow the produce all year round. Vertical growing principle ensures efficient usage of space and water as well as optimal application of needed nutrients and protective agents for the growth produce. The customer receives on-spot training on vertical cultivation under artificial lighting.

The basic module of the growing system consists of:

- 6 growing shelves; each of total area 4,158 m2. shelf dimensions 1.35 m x 0.55 m.

- CC tray, used to irrigate the system; dimensions 1.26 m x 0.55 m x 0.035 m.

- High-end EU-made professional LED luminaries for growing used by the leading agricultural and horticultural institutions.

What can you grow?

Herbs & Microgreens

- Lettuce

- Tomato

- Mint

- Spinach

- Oregano

- Thyme

- Arugula

- Coriander

- Chives

- Dill

- Basil

- Pepper

- Flax

- Tarragon

- Mustard greens

- & much more

Boost nutrition intake. No chemicals or pesticides. Production increases 3 to 10 times in the same amount of space.

Mushrooms

- Oysters

- Nameko

- Shiitake

- Lion’s mane

- Maitake

- Button

- Enokitake

- Turkey Tail

- Cordyceps

- Reishi

- Cinnamon cap

- King Trumpet

- Chestnut

- Maitake

- Pioppini

- Beech

- & much more

Grow mushrooms otherwise unavailable in your area. Grow mushrooms faster. No Seasonality. Grow all year round.

Fodder for Feeding

- Pig

- Cattle

- Rabbit

- Horse

- Chicken

- Cow

- Llama

- Sheep

- Alpaca

- & much more

Easy daily production. Reduced time to grow. Less water is required.

Get all the help you need

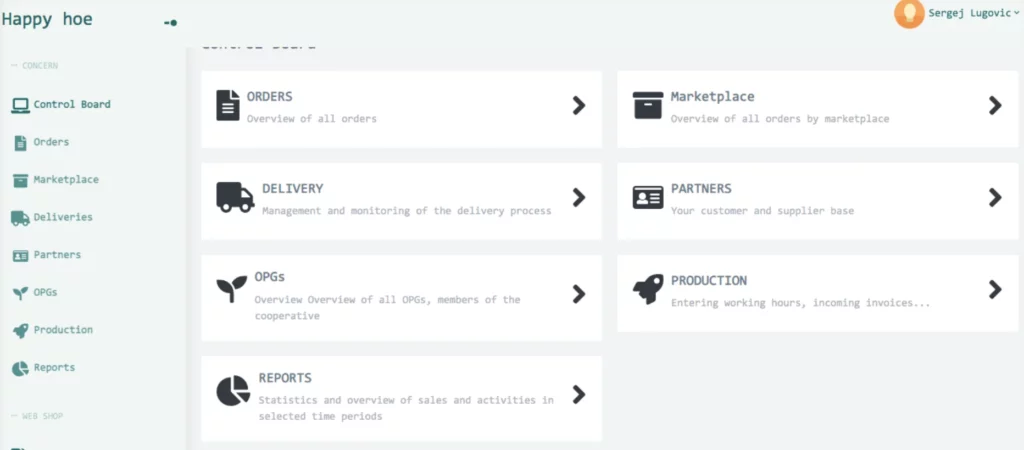

Ecommerce Store

Farming Panel

Distribution Panel

New Customers

We provide full farming service for you from A to Z

Farm design, Workability, Due diligence, Industry Market research, Education & Workshops, Finance

Concept

We create designs according to your vertical farming needs and requirements

Support

We provide training for the staff and 24/7 aftersales support as well as maintenance and supply of raw materials

Due diligence

We research the market and help you choose the strategically important locations

Distribution

We take care of the end product – freshly and locally grown vegetables and greens – distribution and sales.

Manufacture

We make technology and automatization for vertical farms.

Education

We constantly evolve and keep you updated on the latest invitations

Concept

We create designs according to your vertical farming needs

Due diligence

We research the market and help you choose the strategically important locations

Manufacture

We make technology and automatization for vertical farms.

Support

We provide training for the staff and 24/7 aftersales support as well as maintenance and supply of raw materials

Distribution

We take care of the end product – freshly and locally grown vegetables and greens – distribution and sales.

Education

We constantly evolve and keep you updated on the latest invitations

Your Container Farms, Our answers

20-foot shipping container farm costs starting from EUR 44 000.

40-foot shipping container farm costs starting from EUR 69 000.

Container farms can be equipped with solar panels and suited for operating off-grid.

Our solutions are fully equipped, automated and ready to operate

Each unit has been insolated with polyurethane foams.

Our insulation solution eliminates termal bridges.

An example: a single 40-foot container farm can produce up to 500kg of microgreens per month. Depending on the microgreen local retail price per kg (prices vary from 25 to 80 EUR/kg in Europe), it is possible to generate on average 20 000 EUR/month from a single container farm.

Hydroponics systems are methods of growing plants without soil, using nutrient-rich water instead. There are several different types of hydroponics systems, including:

- Ebb and flow (flood and drain) system

- Nutrient film technique (NFT)

- Deep water culture

Hydroponics systems have several advantages over traditional soil-based farming methods. They can be more water-efficient, as the water in the system can be recycled and reused. They also take up less space, as the plants are grown in a smaller area. In addition, hydroponics systems allow for greater control over the growing environment, as the nutrient levels and pH of the water can be easily monitored and adjusted.

Average cargo shipping container in harsh conditions eg. wind, salt water last approximately 13 years. With right modification it can last much longer.

Pros of growing plants in a shipping container include:

- Space efficiency: Shipping containers are relatively small, which can make them a convenient and space-efficient option for growing plants, especially in urban areas where space is at a premium.

- Water efficiency: Hydroponics systems used in shipping container farms can be more water-efficient than traditional soil-based farming methods, as the water in the system can be recycled and reused.

- Control & Automation: The controlled environment of a shipping container farm allows for greater control over the growing conditions, such as temperature, humidity, and nutrient levels, which can lead to improved plant growth.

Cons of growing plants in a shipping container include:

- Limited space: The small size of shipping containers can limit the amount of plants that can be grown.

- High upfront cost: The initial cost of setting up a shipping container farm can be quite high, especially if you are purchasing new shipping containers and installing advanced hydroponics and climate control systems.

- Limited customization: The size and shape of shipping containers can make it difficult to customize the layout of the farm to suit your specific needs.

Most shipping containers are made from COR-TEN steel, which is strong, durable, and resistant to corrosion. If rust are not handled carefully they are at risk of rusting. As with many things, prevention is the first—and best—step in solving a problem. With new containers its less risk thou.

Shipping containers are made from corrugated steel and are designed to withstand the harsh conditions of ocean shipping. However, like any metal structure, they are susceptible to rusting over time. The rate at which a shipping container will rust will depend on a number of factors, including the climate in which it is located and the level of maintenance it receives.

Shipping container farms can be used in both hot and cold climates, although some modifications may be necessary to optimize plant growth in extreme temperatures.

In hot climates, it may be necessary to provide additional cooling to the shipping container farm to keep the plants at a suitable temperature. This can be achieved through the use of air conditioning or by using reflective materials on the exterior of the containers to reduce the amount of sunlight that enters the container.

In cold climates, it may be necessary to provide additional heat to the shipping container farm to keep the plants warm enough. This can be achieved through the use of heating elements or by using insulation on the exterior of the containers to reduce heat loss. It is also important to ensure that the shipping container farm is protected from strong winds and freezing temperatures, as these can damage the plants and make it difficult for them to thrive.

20′ HC shipping container mushroom farm costs starting from EUR 39 000.

40′ HC shipping container mushroom farm costs starting from EUR 59 000.

Container farms can be equipped with solar panels and suited for operating off-grid.

Our solutions are fully equipped, automated and ready to operate

Your contact information

We will contact you within 24 hours.

We make amazing things real

We provide fully equipped vertical farming container units ready-to-grow.

We customize vertical farming solution for your desired local produce.